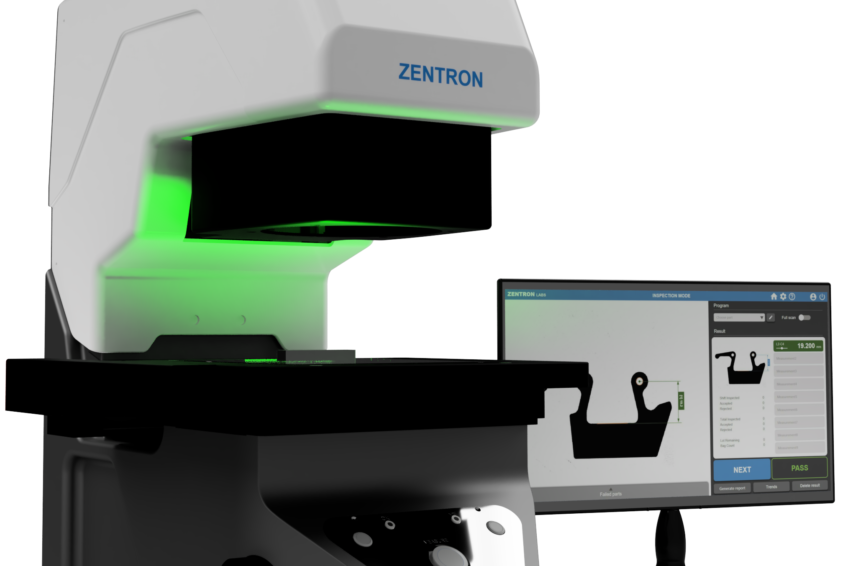

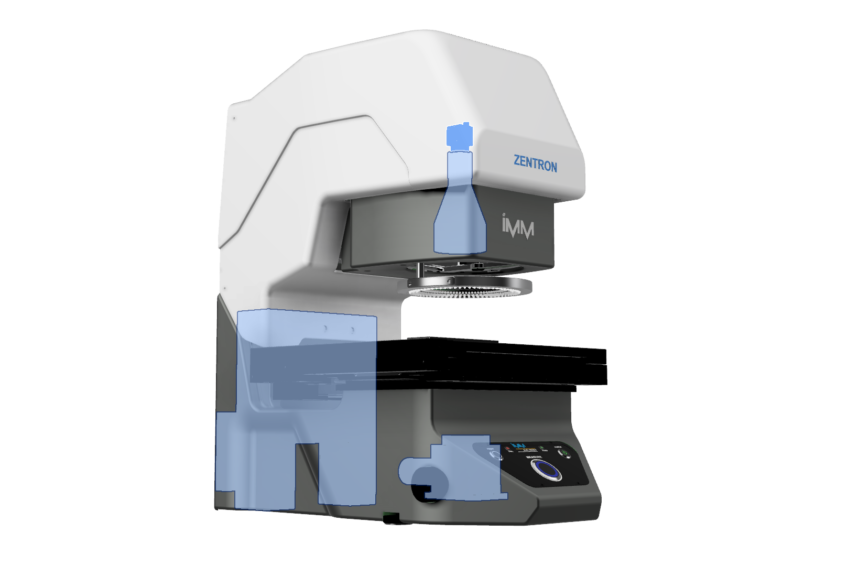

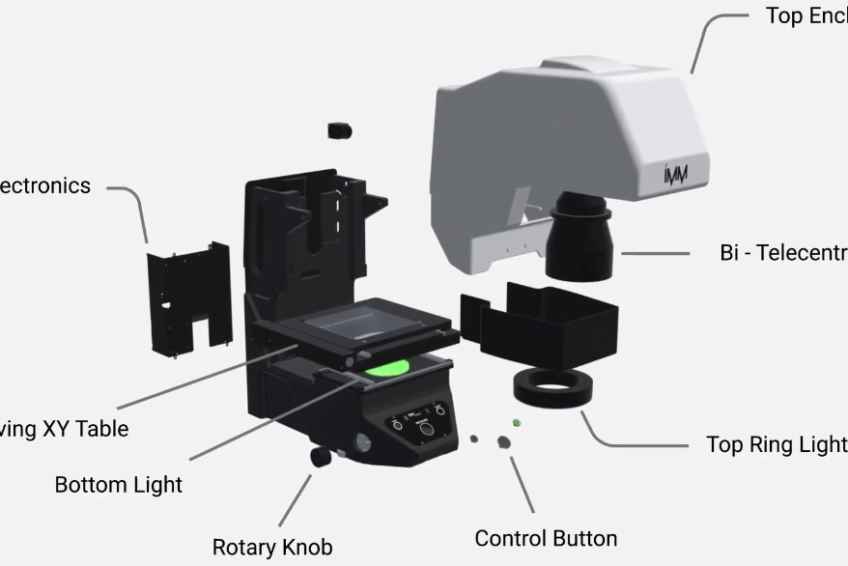

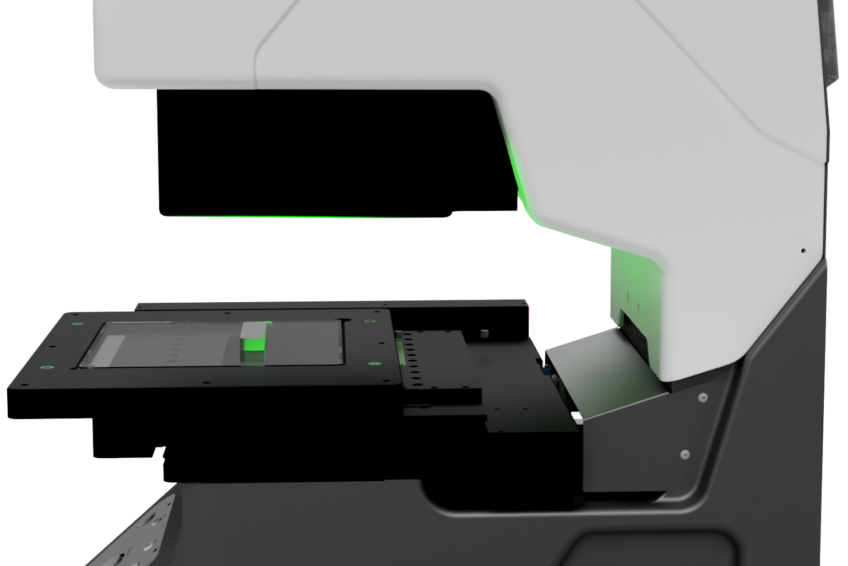

iMM – Instant measurement machine is a tabletop, vision based inspection system that measures multiple dimensions with a single touch of a button.

Accuracy: +/- 3 microns

Repeatability: 1.5 microns

Key features of iMM:

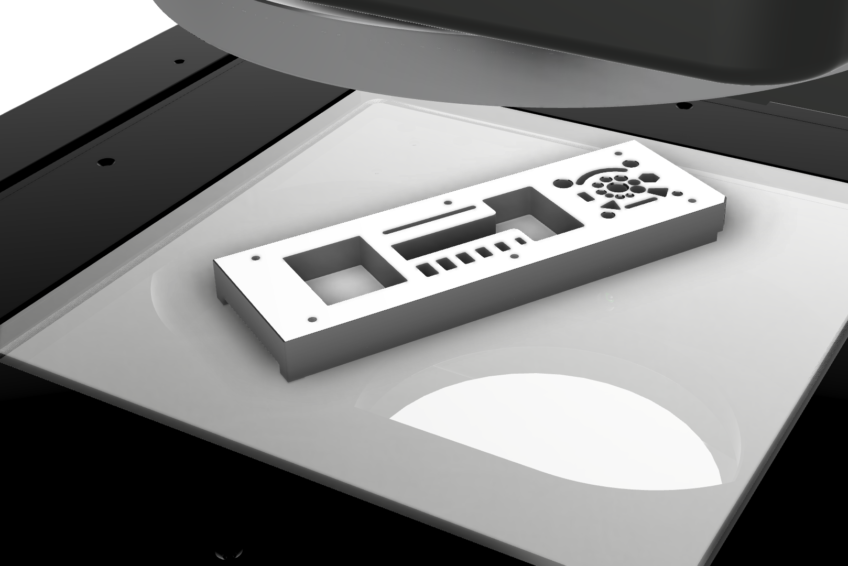

1. One touch: Just place the part on table and press a button.

2. Instant inspection: Inspection cycle time is less than 3 s.

3. User independent: Part can be placed in any orientation and at any place on the table. Anybody in the plant can use the system without training.

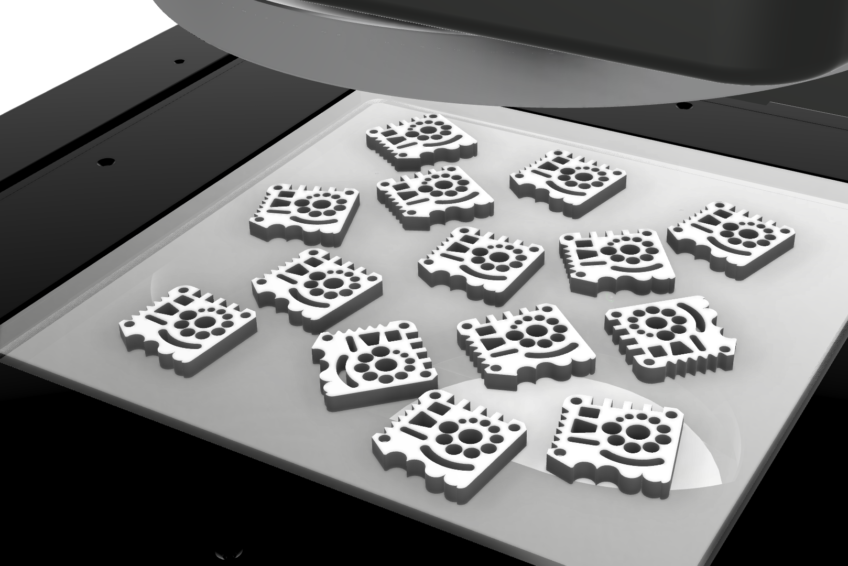

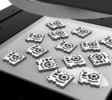

4. Multi-part inspection: Multiple parts can be inspected simultaneously.

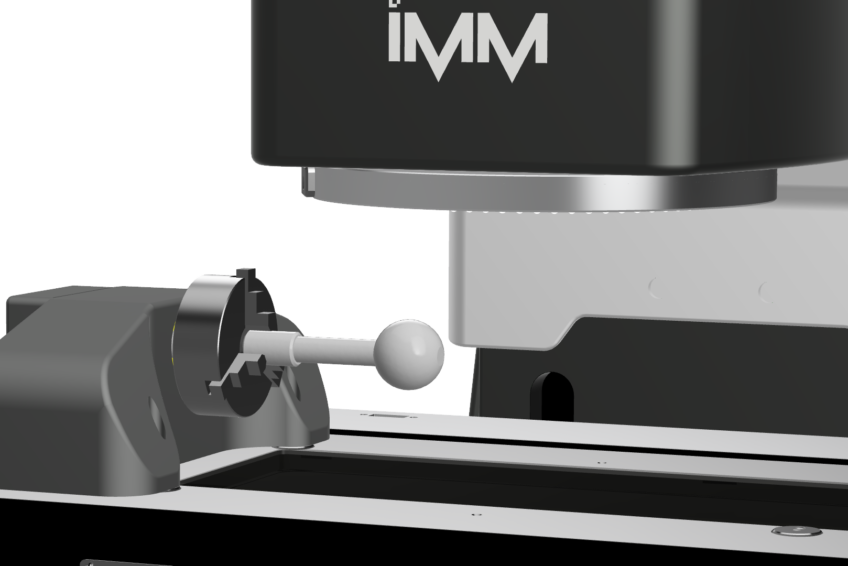

5. Multi-view inspection: Inspect up to five views of a part in a single inspection cycle.

6. DXF import: CAD drawing can be imported to configure the parts.

7. Profile(contour) inspection: Measures the difference between true profile and part’s profile.

8. Data analytics: Compilation of data and images for part reports along with history. Computation of Cp / Cpk, average & trends with graphical representation.